Pressure Drop Calculation Guide and Engineering Notes

When Should You Use This Pressure Drop Calculator?

The pressure drop calculator is a powerful tool for calculating pressure loss in pipelines, tubing, and duct systems. It is ideal for engineers, designers, and professionals working with Newtonian fluids (liquids and gases) in closed, round, or rectangular ducts.

This pipe pressure drop calculator applies to incompressible flow, where the fluid density remains constant. It accurately determines pressure loss due to friction, pipe diameter, pipe length, and velocity changes.

If the fluid is a gas, ensure that pressure changes remain within 5-10% of the initial pressure. If the pressure drop exceeds this limit, use a compressible gas pressure drop calculator for more accurate results.

For gas calculations, the ideal gas law is applied, assuming perfect gas properties to compute unknown values such as pressure, temperature, and density.

This pressure drop in pipe calculator works for both laminar and turbulent flow regimes, making it applicable for various industries, including oil and gas, HVAC, and water distribution systems.

When Is This Pressure Loss Calculator Not Applicable?

- Compressible Gas Flow: If gas pressure changes exceed 10%, use a compressible gas pressure drop calculator.

- Non-Newtonian Fluids: The pressure loss in pipe calculator does not support fluids with viscosity changes due to shear rate variations.

- Multiphase Flow: This pipeline pressure loss calculator is unsuitable for fluids containing solid particles, gas-liquid mixtures, or slurries.

- Non-Ideal Gases: The piping pressure drop calculator assumes an ideal gas law, making it inaccurate for gases with varying thermodynamic properties.

- Temperature-Dependent Viscosity: If viscosity changes significantly due to temperature fluctuations, this pressure drop through pipe calculator may not provide precise results.

Key Features of the Pressure Drop Calculator

This pressure drop calculation tool is built to handle a wide range of applications. Key features include:

- Calculation of pressure drop and flow rate in pipelines, tubing, and ductwork.

- Supports both laminar and turbulent flows, ensuring accuracy across different flow regimes.

- Applies to water, air, oil, and gas systems, making it a versatile tool for engineers.

- Accounts for pipe diameter, pipe length, viscosity, and velocity changes.

- Works for closed-loop and open-loop systems, ensuring precise results for different designs.

Why Use a Pipe Pressure Drop Calculator?

Accurate pressure drop calculation is essential for designing efficient piping systems. Whether you are working on an HVAC system, an industrial pipeline, or a water supply network, minimizing pressure loss ensures optimal performance and energy efficiency.

Using this pressure loss calculator water can help optimize pump selection, reduce energy consumption, and prevent unnecessary maintenance costs due to high pressure losses.

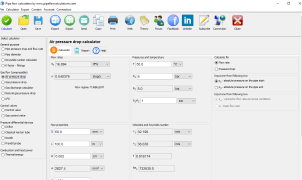

How to Calculate Pressure Drop in Pipe?

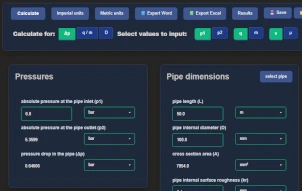

To determine pressure loss in tubing or pipelines, input the following parameters into the pressure drop in pipe calculator:

- Fluid Type: Select water, gas, oil, or other Newtonian fluid.

- Pipe Diameter and Length: Enter inner diameter and total pipe length.

- Flow Rate and Velocity: Specify the flow rate or velocity of the fluid.

- Fluid Viscosity and Density: Input viscosity and density based on the operating temperature.

With these inputs, the pressure loss pipe calculator computes pressure drop per unit length and total pressure loss across the pipeline.

For water applications, the water pressure drop calculator or water pressure loss calculator provides highly accurate calculations. If working with narrow tubing, the pressure loss in tubing tool is recommended.

By using the right pressure drop calc, you ensure accurate, efficient, and optimized pipeline performance.

The following example explains why pressure drop calculations are required instead of simple unit conversions when relating flow rate and pressure.

Why GPM Cannot Be Directly Converted to PSI

Many people ask how to convert gallons per minute (GPM) to pounds per square inch (PSI), but a simple conversion is not possible. PSI measures pressure, while GPM measures flow rate. To determine PSI for a given GPM, you need to calculate the pressure drop using fluid dynamics principles.

Pressure Drop Calculator allows you to find the required pressure loss in PSI based on flow rate, pipe characteristics, and fluid properties.

1. Go to the Pressure Drop Calculator

Go to

Pressure drop calculator.

2. Enter Flow Rate (GPM)

Input your flow rate in gallons per minute (GPM).

3. Specify Pipe Details

Enter the following pipe parameters:

- Pipe diameter (in inches or mm)

- Pipe length (longer pipes create more friction loss)

- Pipe roughness (depends on material type)

4. Enter Fluid Properties

Input or select the fluid type (e.g., water, oil, air). The calculator considers:

- Density (ρ) in kg/m³ or lb/ft³

- Viscosity (μ) in cP or Pa·s

5. Calculate the Pressure Drop

The calculator applies the Darcy-Weisbach equation to determine pressure loss.

6. Understanding the Results

The calculator provides the pressure drop in PSI, which represents the pressure required to maintain the specified GPM flow rate. If your system does not meet this pressure, consider:

- Increasing pump power

- Using a larger diameter pipe

- Reducing pipe length or minimizing bends

Why You Cannot Convert GPM to PSI Directly

Since PSI depends on pipe resistance, fluid properties, and flow conditions, a simple GPM-to-PSI converter does not exist.

Instead, Pressure drop calculator

provides accurate results based on real-world fluid dynamics equations.