Description

- H - pump head

- Pump head required to provide required flow rate q

- p₂-p₁ - pressure difference

- Pressure difference between pipe end and pipe start

- Δp - pressure drop

- Pressure drop due to friction and minor loses along the pipeline

- q - volume flow rate

- Fluid flow rate in terms of units of volume per unit of time

- ṁ - mass flow rate

- Fluid flow rate in terms of units of mass per unit of time

- h - height difference

- Difference in height between pipeline inlet and outlet point

- L - pipe length

- Length of a pipe in which pressure drop is calculated

- D - pipe diameter

- Internal circular pipe diameter

- kr - pipe roughness

- Pipe internal surface roughness

- V - velocity

- Flow velocity in terms of units of distance per unit of time

- A - area

- Internal pipe cross section area

- f - friction coefficient

- Coefficient of friction for pressure drop due to friction calculation

- Re - Reynolds number

- Dimensionless number representing viscous versus inertial forces ratio

- ρ - fluid density

- Mass per unit of volume

- ν - kinematic viscosity

- Result of fluid particles colliding to each other and moving at different velocities in terms of area per square unit of time

- μ - dynamic viscosity

- Result of fluid particles colliding to each other and moving at different velocities in terms of mass per square unit of distance and time

- K - minor resistance factor

- Coefficient used for calculation of minor losses due to local resistances in pipe line like bends, tees, reducers, valves, etc.

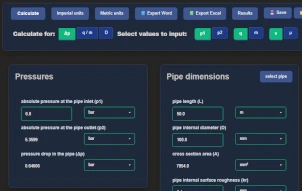

How to Configure the Calculation

The pump head calculator is easy to use and a very reliable tool for solving

practical engineering problems on a daily basis.

The required pump head is determined as follows.

First, it is necessary to enter the parameters provided in the calculator,

primarily the fluid density and viscosity, flow rate,

pipeline length, internal pipe diameter, internal pipe surface roughness,

minor loss coefficient,

elevation difference of the pipeline, and the pressure difference

between the inlet and outlet points.

The calculator automatically calculates all remaining parameters

and finally determines the required pump head.

To simplify the use of the pump head calculator, there is an option to select

a standard pipe from a list of available pipe standards.

In addition, the calculator includes a list of commonly used fluids,

which facilitates the input of the required physical properties:

density and viscosity needed for pump head calculation.

The calculator allows you to select which physical quantity you want to enter

and provides the option to choose between volumetric and mass flow rate,

as well as between kinematic and dynamic fluid viscosity.

If the calculation of the required pump head involves a system where pressure

is present at one end of the pipeline, this pressure can be entered into the

calculator using the pressure difference parameter p2-p1.

For example, if there is a tank at the end of the pipeline with a pressure of 2 bar,

this pressure can be entered into the calculator as a value in the

p2-p1 pressure difference field (2 bar),

and the calculated pump head will take this value into account.

Difference Between Pump Head and Pressure Drop

Pressure drop represents energy losses in the piping system, while pump head

represents the total energy that the pump must provide to overcome those losses,

static elevation difference, and velocity changes.

Pump Head Calculation Guide

When Should You Use This Pump Head Calculator?

The pump head calculator is a powerful tool for quick and easy calculating required pump head in piping system. It is ideal for engineers, designers, and professionals working with incompressible fluids (liquids) in closed, round, piping systems.

This pump head calculator applies to incompressible flow, where the fluid density remains constant. It accurately determines head required to overcome losses in the pipelines due to friction, pipe diameter, pipe length, and velocity changes.

If the fluid is a gas, ensure that pressure changes remain within 5-10% of the initial pressure. If the pressure drop exceeds this limit, use a

compressible gas pressure drop calculator for more accurate results.

This pump head calculator works for both laminar and turbulent flow regimes, making it applicable for various industries, including oil and gas, HVAC, and water distribution systems.

When Is This Pump Head Calculator Not Applicable?

- Compressible Gas Flow: If gas pressure changes exceed 10%, use a

compressible gas pressure drop calculator.

- Non-Newtonian Fluids: The pressure loss in pipe calculator does not support fluids with viscosity changes due to shear rate variations.

- Multiphase Flow: This pipeline pressure loss calculator is unsuitable for fluids containing solid particles, gas-liquid mixtures, or slurries.

- Temperature-Dependent Viscosity: If viscosity changes significantly due to temperature fluctuations, this pressure drop through pipe calculator may not provide precise results.

Key Features of the Pump Head Calculator

This pump head calculation tool is built to handle a wide range of applications. Key features include:

- Calculation of required pump head including pipe friction losses.

- Supports both laminar and turbulent flows, ensuring accuracy across different flow regimes.

- Applies to water, oil and other liquids, making it a versatile tool for engineers.

- Accounts for pipe diameter, pipe length, viscosity, and velocity changes.

- Works for closed-loop and open-loop systems, ensuring precise results for different designs.

Why Use a Pump Head Calculator?

Accurate pump head calculation is essential for selecting an efficient pump and ensuring reliable system operation. Whether you are working on an HVAC system, an industrial pipeline, or a water supply network, minimizing pressure loss ensures optimal performance and energy efficiency.

Using this pump head calculator can help optimize pump selection, reduce energy consumption, and prevent unnecessary maintenance costs due to high pressure losses.

How to Calculate Pump Head in Pipe?

To determine required pump head in tubing or pipelines, input the following parameters into the calculator:

- Height: Enter height difference between entering point and exiting point of the pipeline. For circulating systems this value is 0

- Pressure difference: Enter pressure difference from entering and exiting points of pipeline, if any. This difference is not pressure loss due to friction.

- Fluid Type: Select water, oil, or other Newtonian liquid.

- Pipe Diameter and Length: Select standard pipe or enter inner diameter and total pipe length.

- Flow Rate: Specify the flow rate of the fluid.

- Fluid Viscosity and Density: Select fluid or input viscosity and density based on the operating temperature.

With these inputs, the pump head pipe calculator computes pump head and total pressure loss across the pipeline.

By using the right pump head calculator, you ensure accurate, efficient, and optimized pipeline performance.

Once the required pump head is calculated, proceed to the

pump selection calculator

to determine the operating point and select the appropriate pump.